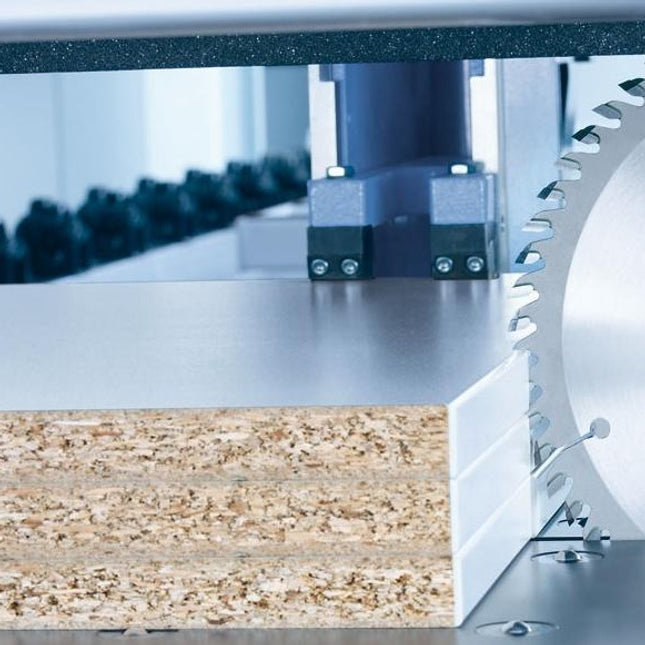

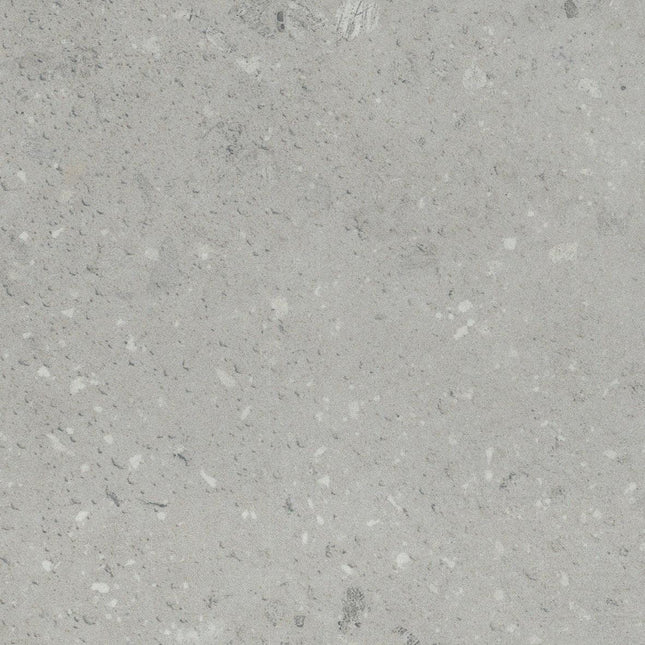

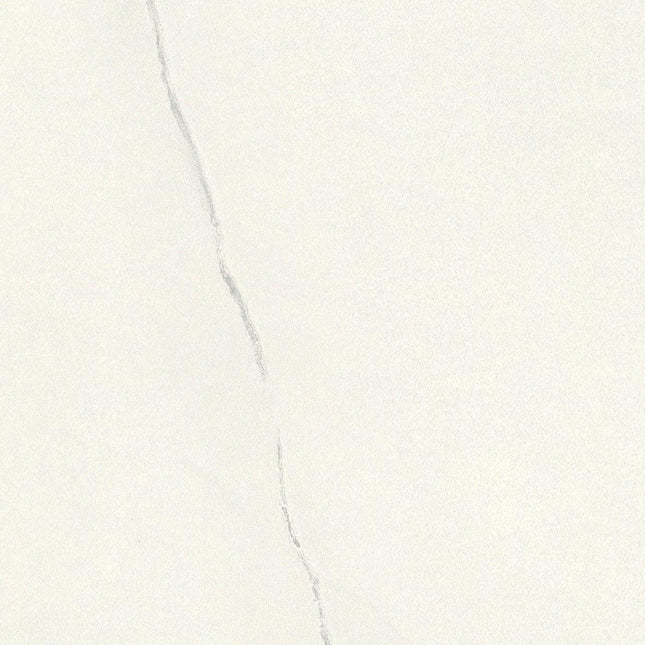

Duropal Quadra Laminate Benchtops 38mm

$242.00 - $363.00

$22.00 - $44.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

$660.00

$242.00 - $363.00

$242.00 - $363.00

Online Sale Only

$181.50 - $297.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

$242.00 - $363.00

While Stocks Last !

$220.00 - $330.00